VIZHAG WTE PROJECT

Andhra Pradesh, IndiaConvalt is negotiating with lenders for financing RIPL-GP´s 7.5 MW Waste-to-Power Project at Kothavalasa Village, Vizianagaram district of Andhra Pradesh, India.

Convalt is negotiating with lenders for financing RIPL-GP´s 7.5 MW Waste-to-Power Project at Kothavalasa Village, Vizianagaram district of Andhra Pradesh, India.

Project development

Permits & Approvals

Construction Start Date (targeted)

Commercial Operation Date (targeted)

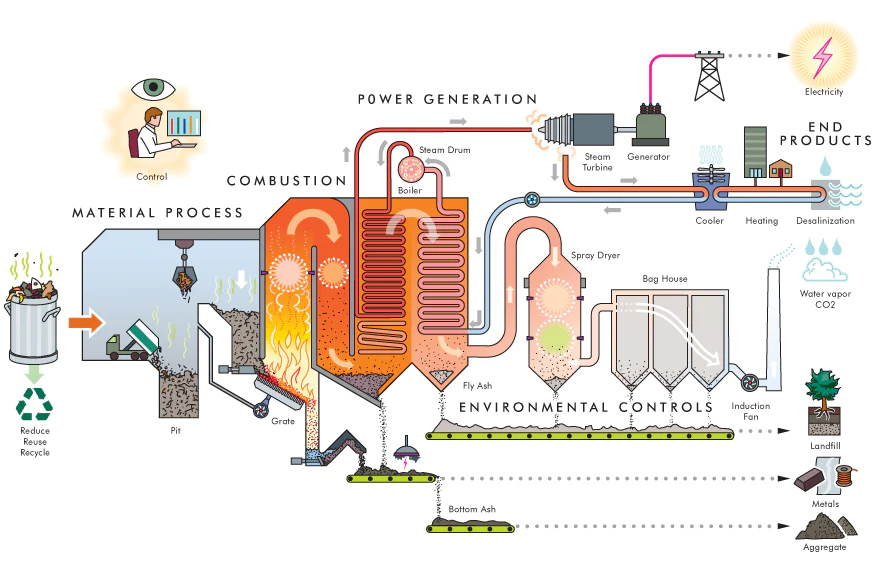

Thermodyne Technologies. Bi-drum Water Tube Boiler, Top Supported, Pneumatic Spreader with Travelling Grate. Max Continuous Rating (MCR) 40tons/hr.

Triveni Turbines. Turbine system consisting of Multistage Turbine, Gearbox, Coupling, Governing system, Lubricating system, Accessories, AC Generator, Control and instrumentation, and Panels for operation, protection and synchronization for generating power up to 8 MW.

Paharpor Cooling Towers Ltd. Air Cooled Condenser (ACC) which facilitates reduced water consumption, to condense steam vapors from the turbine.

The TG generates power at 11 kV level. In-house power requirement is met by stopping down

the voltage level to 415 V through a step down transformer.

The surplus power of 6.75 MW is stepped up to 33kV level and connected to the APTRANSCO

sub-station at Melumai which is at a distance of approximately 2 km from the plant.

The raw water for chemical treatment comes from the transfer pump of main water storage reservoir. The RIPL_GP DM plant is sized to meet the makeup requirement of the steam. The DM plant consists of two streams of adequate capacity each. Each stream has pressure filter, RO plant, Cat-ion, An-ion, De-gaser, mixed bed system. The system is parallel connected and manually operated.

The Distributed Control System (DCS), custom designed and installed by VRL Automation Limited, facilitates the centralized management of the entire power plant. The following are the components of DCS deployed at RIPL-GP.

The plant utilizes dual Belt Conveyer Systems for fuel handling inclusive of seperate storage bunkers and hoppers.

One Belt Conveyer System is used for Poultry Litter and Husk while the second Belt Conveyer system is used for other materials.